Earth back-filling and Compaction

Earth Backfilling and Compaction

- 1. Always go for approved earth material for back filling. After soil testing, the Soil with Liquid limit > 65% and Plasticity index > 35% should not be used.

- 2. Clay soil is not allowed for backfilling, for the reason being, the characteristic of clay is, it shrinks when dry and expands when wet, results in development of cracks at later Stage.

- 3. Construction debris and soil with organic material like grass, roots, shrubs and vegetation are not to be used for backfilling.

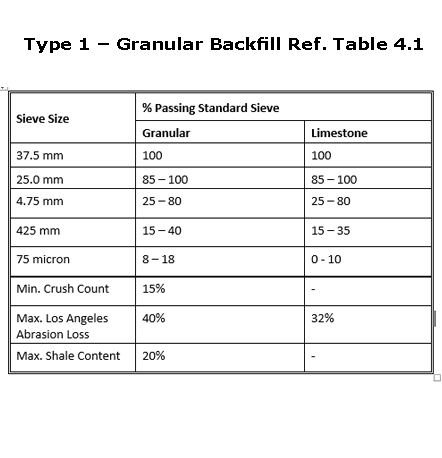

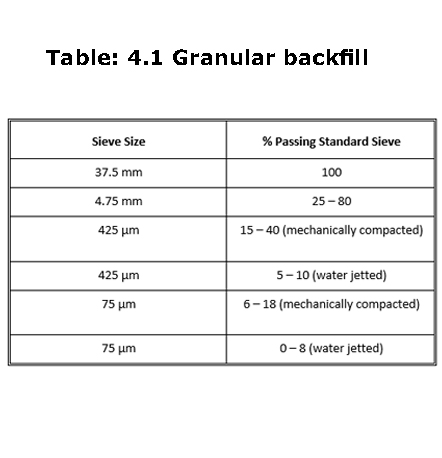

- 4. Backfill material shall confirm to one of the following types:

- Table: 4.2 Gravel backfill

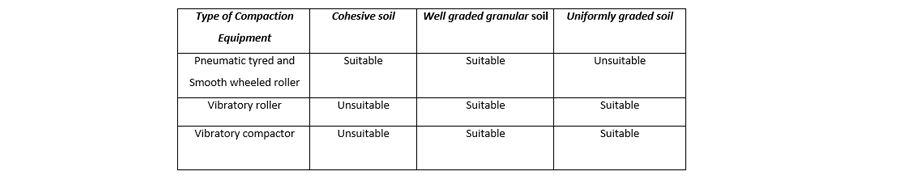

- 5. The process of Compaction is to be done in layers of 150mm depth. Based on the nature of soil, the compaction equipment will be selected.

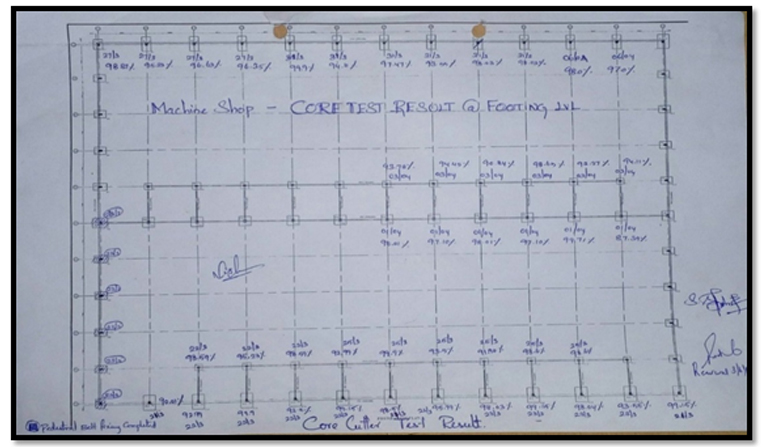

6. Field Density of Soil : Earth backfilling to be done with Proper consolidation, compacted at optimum moisture content to a minimum of 95% standard proctor density or Field dry density FDD for all i) Footings up to top level, ii) Inside and Outside Plinth and iii) Below Granular sub base (GSB) level. Sand replacement method or Core cutter method is to be used to ascertain insitu field density of soil.

Fig. 1 FDD readings for all column footings location inside and outside the building

- 7. Sometimes, if weak strata of soil is found in excavated trenches, footings and any other foundation areas, this has to be removed completely and replaced by strong compacted earth depending upon the type of structure, loads coming over foundations etc.

- 8. Advise: Actually before starting excavation work, it is very much important, that the strength and stability of soil at various depths of foundation with respect to the Natural ground level (NGL) of soil is to be determined by conducting soil exploration with reputed agency. (We will discuss the same in our future article)

- 9. Caution: During excavation in all types of soil and all weather conditions, there might be chances of earth sliding, sudden earth collapse, percolation of water in foundation trenches, seepage of water from sides or bottom, all these factors not only affect the work but results in safety of men working at the location. (We will discuss this in our future article) It is the responsibility of Project manager and safety manager to anticipate and foresee the problems, to take necessary safety measures from starting to completion including updated documents.

- 10. The volume of backfilling for the designated area to be estimated, plan accordingly before the actual work starts and always keep extra cushion of 25 to 30 % quantity to accommodate loose earth volume to compacted earth volume.

Fig. 2 Use Plate vibrators for Compaction of earth, inside of larger footings

Use Monkey jump compactor of earth in confined areas

Layer by layer compaction process using 3 ton roller for larger areas after completion of backfilling

Layer by Layer compaction process using 1 ton vibro roller

Compaction testing

Using plate vibrator for compaction inside large footings after completion of backfilling

Connect with us to avail a complete construction services

CONTACT US

15/4, gurunath 2 A cross Hanumagirinagar, Chikkallasandra Main Road Subramanyapura,

Bengaluru – 560061

info@myhomemydesign.in

Our Happy Clients

Client Testimonials

I whole heartily congratulate the unique website “My Home My Design’ which gives immense pleasure and information about construction aspects. The top categories covers all topics of civil engineering & construction technology, highly useful to professionals & people wants to build their houses in a complete satisfactory manner without lack of engineering knowledge. Now they can proudly feel the happy results. I look forward more and more information in future which benefits all people throughout the country.

Shri Srinivasa Narasimaiah is a highly knowledgeable, practical man strict to the Quality Principles in construction methods as well as materials and not comprising at any cost.

LLP, Ex-President- RMC Readymix (India)

With 27 Plus years of vast Experience in construction field, Shri N.Srinivasa is Chief Quality Auditor, guide,strength &backbone for all our projects as far as quality & workmanship is concerned.

Really superb, this website shares immense knowledge about A- Z of construction activities in a standard and technical way. The ideas, caution, advice at suitable places highlights the creator’s practical exposure and experience in the subject. Similarly photos, description and videos gives immense knowledge for all construction aspects. I wish all the success for this website and likewise spread this useful information to the people across the globe.

PraveenShrusti Design Consultants

Shri Srinivasa Narasimaiah was the main pillar behind our Prana Medical centre construction from start to finish including Plan, Construction, Quality, workmanship and timely completion.Without his cooperation the project wouldn't have been completed on time.

MBBS and Chairman at PRANA MEDICAL CENTER, SPECIALIST CENTER FOR DIABETES, ENDOCRINE,

OBESITY. – Kodambakkam – Chennai- 600024

Previous

Next

Always Dedicated & Devoted

Latest Projects

Excavation for basement and footing

October 16, 2019

Compaction of Concrete

October 10, 2019

Building ByeLaws for Residential Buildings – All You Wanted to Know

September 22, 2019

How to Plaster Your House? Guide for Home Plastering

July 19, 2019

EXTERIOR PAINTS – PAINTING WORKS

July 19, 2019

CONCRETE – RCC WORKS IN CONSTRUCTION – PART1

July 19, 2019