Waterproofing Works in Bangalore

Waterproofing Contractors in Bangalore

Like all civil construction works, Waterproofing works in Bangalore or anywhere is plays very important role in construction industry as well as in public life.

This Waterproofing in Bangalore for buildings of any type whether it is new, existing or under construction, has to be tackled carefully with complete engineering knowledge, field experience, quality materials and by reliable professional agency, contractor or team of people.

While doing work, closely observe all minute details and see that no dampness or leakages are found anywhere in pipe line, taps, floors or walls. Standing Water test over terrace floor, sunken floor, utility and bathrooms is highly advisable and useful to be done after completion waterproofing works.

All these above points and even more will be carried out by our company called My Home My Design have an expert team that handle waterproofing works in Bangalore or anywhere by professional waterproofing contractors, team of experts as per engineering quality standards.

These quality standards of Waterproofing works in Bangalore or anywhere should follow the procedure for all new construction works like surface preparation, water leakage test, Base coat, Fiber reinforced mesh, screed concrete, brick bat coba, final finishing, curing etc., explained in detail with suitable photos and videos in this WEBSITE.

Glimpses of Our Waterproofing in Bangalore

- Prompt and reliable waterproofing services in Bangalore.

- Best and reasonable services, for all types of residential buildings, apartments, commercial complexes, Industrial, healthcare units etc.

- Trying level best waterproofing solution Bangalore for challenging and emergency works, dampness and leakage issues.

- Usage of right material, tools, equipment, latest ideas and technologies to addressing all kinds of waterproofing issues irrespective of quantity of work.

- Professional certified Waterproofing contractors in Bangalore and experienced team of works

- Attending your needs of Waterproofing treatment for all RCC works like UG sump, retaining wall, sunken floors, terrace floors, overhead water tank , pressure grouting works, swimming pool and all expansion joints treatment works etc.by Waterproofing experts in Bangalore

- Cracks filing, basement treatment, tiles grouting etc.,

- Special treatments like Epoxy coating, water proofing Membrane, PU coating, acrylic water proofing coating, Polystyrene Thermal Insulation Boards etc.,

Connect with us to avail a complete construction services

Waterproofing works for RCC flat, sloped

roofs and sunken slabs

Tools to be used for Waterproofing works

Mason’s brush, Chipping tools, Wire brushes, Soft brushes, Air compressor, wheel barrow, paint brushes, plumb bob, sponge, Tube level, Aluminium straight edge, hammer, water barrel, spirit level, scissors, cutters, Gas cylinder, bitumen roller,dumpy level, line thread, sprit level, wooden mallet.

Mason’s brush, Chipping tools, Wire brushes, Soft brushes, Air compressor, wheel barrow, paint brushes, plumb bob, sponge, Tube level, Aluminium straight edge, hammer, water barrel, spirit level, scissors, cutters, Gas cylinder, bitumen roller,dumpy level, line thread, sprit level, wooden mallet.

Surface preparation and screed concrete works for flat and sloped roof waterproofing works

Surface preparation :

- Is the most important aspect before carrying out waterproofing works for any concrete surface

- Using appropriate chipping tools and brush, the surface should thoroughly chipped and free from existing cement mortar, dead mortar, concrete deposits, dust and all kinds of loose material.

Water leakage test :

- Water leakage Test is to be done by filling the concrete surface with standing water by making ponds, and if any leakage or dampness visible, to be clearly marked by using crayons in the respective ceiling below the terrace.

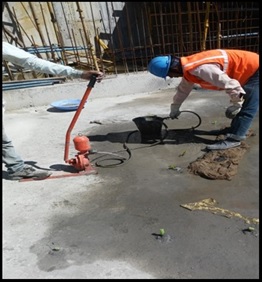

- After this, depending on the depth of dampness, a 12 mm diameter GI nipples to be inserted on the ceiling locations.

- The cement pressure grouting procedure, admixed with water proofing compound from top of the roof to be done, through these GI nipples until the grouting reaches the bottom surface.

V-Grooves : For all joints of brickwork, block work or concrete junctions, cracks appeared to be widened by making V grooves along the joints and filled with suitable sealant material.

Fiber reinforced mesh : All rain water pipe lines, plumbing pipe lines to be properly sealed by using a good quality fiber reinforced mesh with first coat plastering, cure it for two days, then go ahead with final coat of plaster as waterproofing works finishing.

Base coat :

- First, base coat or bonding coat is to be applied over concrete surface using cement and polymer additive .

- Over this, apply two coats of Acrylic polymer waterproof coating system or equivalent as per manufacture’s specifications or as per tender document,continuing the application, including overlapping of parapet wall plastering by one foot height.

- This monolithic action of floor with parapet wall serves the strong bonding purpose as well as easy flow of rain water through proper slopes.

Screed concrete :

- After this, provision for slopes, ridges and valleys over the floor to be marked with reference pads as per drawings, with minimum and maximum thickness of 25 to 30 mm to carry out a protective layer of screed concrete.

- Ensure the cement slurry brushing for concrete surface before screed concrete.

- Smooth plastering finishing (mixer of cement and recommended waterproofing compound) to be given for this screed concrete exposed top surface in order to protect the coating from weather conditions.

- Allow it for minimum 24 hours to 4 – 5 days for testing by ponding water at 50 – 100 mm depth, for the effectiveness of water proofing treatment.

- Now the surface is finished by giving smooth finish of Indian patent stone (IPS floor) or with weathering tiles laying by maintain the same profile and slopes of Waterproofing works.

Cement based waterproofing works treatment using brickbat coba for terrace slab

Surface preparation :

- Clean the surface over the slab by removing all loose materials, dust etc. and wash with clean water

- Over this cleaned surface, provide a layer of Cement mortar of 1:3 ratio including water proofing compound with an average thickness of 20 mm.

Brick bats laying :

- Start laying brick bats of 115 mm thick in random pattern, braking monotony of joints with 10 mm thick joints between two bricks, and fill it uniformly.

- Continue the brickbats in a systematic circular pattern, following the slope line, till the end of rainwater outlet provided.

- Try to avoid as far as possible dry brick bats and over burnt brick bats while laying.

- In case the brick bat coba is laid on the base coat instantly on initial set there will be no need of applying cement slurry over the base coat before laying the brick bat coba.

- Conversely, if the brick bat coba is to be laid on the following day, cement slurry is to be applied over the top surface of the base coat and then only the brick bat coba to be laid.

Glass fiber mesh :

- Laying Finishing Layer also called a Protective Coat, Immediately on applying the cement slurry over the surface of the brick bat coba and when the slurry applied is still green, the waterproofing glass fiber mesh of thin approved brand, flexible, chemically resistant borosilicate glass fibre, is to be spread uniformly on the surface without any bend, twist and pressed to see that no air gaps exist.

- Create a haunch portion between the junction of roof and parapet wall using brickbat coba only and continue the fiber glass cloth for parapet walls and inserted in the groove at a height of 300 mm on wall.

Curing :

- Curing to be done for this layer for a minimum of 3 days before taking up the next layer.

- Even if there is any delay for continue the final layer over this layer, curing should not be stopped and continued for a period of at least 10 days.

Final finishing :

- The groove in the parapet wall over the haunches also to be filled neatly, packing the mortar firmly in the groove.

- The surface of the final finishing layer or protective coat is to be neatly finished with cement slurry.

- Then, finished surface shall be allowed to dry for a while and then using 8 mm thick line thread, a pattern of 300 mm x 300 mm groove, is pressed by gently tapping the line thread with wooden mallet, over the entire surface after waterproofing works.

- The entire surface after waterproofing works is to be allowed for air curing for 4 hours and later the surface to be cured with clean water for 7 days.

- On completion of curing, the grooves where the fibre glass cloth is inserted, is to be neatly closed with cement mortar admixed with water proofing compound and the repaired surface should be cured by clean water for 7 days

Sunken slab waterproofing works for bathrooms and toilet floors :

- The procedure is similar for sunken areas of bathrooms and toilets also, and the treatment to be applied for the full depth of sunken portion including water testing, for at least 200 mm depth of standing water in sunken portions.

- Caution: All Electrical chasing works and Plumbing chasing works, boreholes etc. to be completed and properly packed, sealed either by means of fiber mesh, or by water proofing compound including curing, before the commencement of waterproofing treatment.

- Avoid strictly the chasing works after completion of Waterproofing works.

- Cinder : After the treatment, this treated surface to be filled with cinder for full depth, nicely compacted and finished with 75 mm to 100 mm thick screed concrete of M 15 grade and cured for 4 -5 days.

Advice : Bathroom level difference

- In order to maintain the level difference between main floor area and bathroom floor area by preventing toilet water entering into the main area, it is always recommended, to have bathroom floor level by one tile thickness or 20 mm below the main floor.

- Hence unfinished floor or screed concrete level in bath room area is also to be 20 mm below the unfinished floor of main area.

Surface preparation for waterproofing works

Pressure grouting under progress

Base coat application over concrete surface

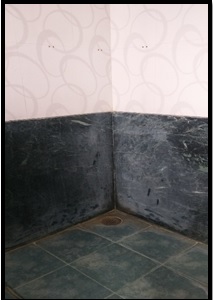

Toilet sunken slab base coat waterproofing works

Curing for toilet sunken slab after completion of waterproofing work

Brick laying over 1:3CM bed for waterproofing works

Cement surface finishing over brick bat coba

Making 8MM deep grooves over finishing surface of waterproof works

CONTACT US

15/4, gurunath 2 A cross Hanumagirinagar, Chikkallasandra Main Road Subramanyapura,

Bengaluru – 560061

info@myhomemydesign.in

Our Happy Clients

Client Testimonials

I whole heartily congratulate the unique website “My Home My Design’ which gives immense pleasure and information about construction aspects. The top categories covers all topics of civil engineering & construction technology, highly useful to professionals & people wants to build their houses in a complete satisfactory manner without lack of engineering knowledge. Now they can proudly feel the happy results. I look forward more and more information in future which benefits all people throughout the country.

Shri Srinivasa Narasimaiah is a highly knowledgeable, practical man strict to the Quality Principles in construction methods as well as materials and not comprising at any cost.

LLP, Ex-President- RMC Readymix (India)

With 27 Plus years of vast Experience in construction field, Shri N.Srinivasa is Chief Quality Auditor, guide,strength &backbone for all our projects as far as quality & workmanship is concerned.

Really superb, this website shares immense knowledge about A- Z of construction activities in a standard and technical way. The ideas, caution, advice at suitable places highlights the creator’s practical exposure and experience in the subject. Similarly photos, description and videos gives immense knowledge for all construction aspects. I wish all the success for this website and likewise spread this useful information to the people across the globe.

PraveenShrusti Design Consultants

Shri Srinivasa Narasimaiah was the main pillar behind our Prana Medical centre construction from start to finish including Plan, Construction, Quality, workmanship and timely completion.Without his cooperation the project wouldn't have been completed on time.

MBBS and Chairman at PRANA MEDICAL CENTER, SPECIALIST CENTER FOR DIABETES, ENDOCRINE,

OBESITY. – Kodambakkam – Chennai- 600024

Previous

Next

Always Dedicated & Devoted

Latest Projects

Excavation for basement and footing

October 16, 2019

Compaction of Concrete

October 10, 2019

Building ByeLaws for Residential Buildings – All You Wanted to Know

September 22, 2019

How to Plaster Your House? Guide for Home Plastering

July 19, 2019

EXTERIOR PAINTS – PAINTING WORKS

July 19, 2019

CONCRETE – RCC WORKS IN CONSTRUCTION – PART1

July 19, 2019